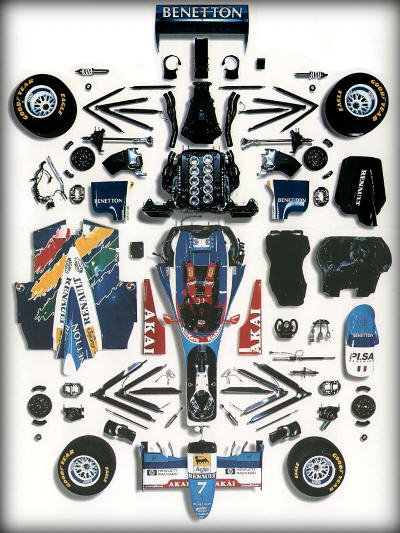

| The making of a

Formula One car

Team solidarity and

performance are key parts to the success of any area of a

Formula One team. But none more so than in the process of

designing, developing and constructing the race car

itself.

This is a paramount

process and Operations Director Joan Villadelprat

is quick to acknowledge that teamwork plays an intrinsic

role as the car takes to life from computer screen to

race track.

"It is everything

really, he confirms. Each area is worked specifically by

certain people and they all need to gel together. You

have people working on composite, machinery, fabrication,

assembly -from people putting the car together to the

painter. It is a team effort all the way."

Joan estimates the birth

of a Formula One car takes 'normally' up to five months

and as the car begins to reach the final product, the

team members involved, simultaneously increase.

"Firstly it starts

off at the drawing office and then production gets

involved and then everyone gets involved, so the whole

company works towards the same end," he

explains. "You probably have 30 people to start

with, then you end up with about 110, and then by the end

you have everyone else."

A long and exacting

process, the advent of new rules and regulations with

increasing competition does not just have its affects in

the heat of the race, but also in the walls of the team

factory, as Joan highlights the one piece of machinery

which is attributed most time on.

"We have some new

systems in the B197 this year. Power steering is one of

many new items we have never had in the car before and

the implementation of these needs to be included in the

schedule which you try to stick to."

"From our side,

because we do not produce the engine, the gearbox the

gearbox takes the longest to make. It takes four and a

haklf months and you have a dedicated group of people

working on it. At the end of the day when the chassis is

done it takes very little time, but the gearbox is a

delicate part.

"First you have to

do the design and then patterns before the castings are

done. These have to be confirmed and then you need to

machine the castings, do the internal arrangements, so it

is quite a big job."

And mistakes.... "Mistakes

at the different stages get caught in the methods and

systems we have in the company. From the inspection

department to quality control."

BENETTON-RENAULT B197 -

COUNTING THE COST

· Gearbox -

between casting and

machining £10,000 added.

with internals,another

£100,000

· Brake calipers

£28-29,000

· Tyres (each)

£600

(supplied by Goodyear)

· Nose cone

£10,000

· Chassis £70,000

· Wings(rear}

£4-6000

· Engine cover

£3,000

Formula 1 Contents

|